JRA hubs by Bitex

We used the best hubs we could find for our range of wheels and hubs: Bitex. We have ridden them extensively and we are convinced that they offer outstanding durability, reliability and serviceability.

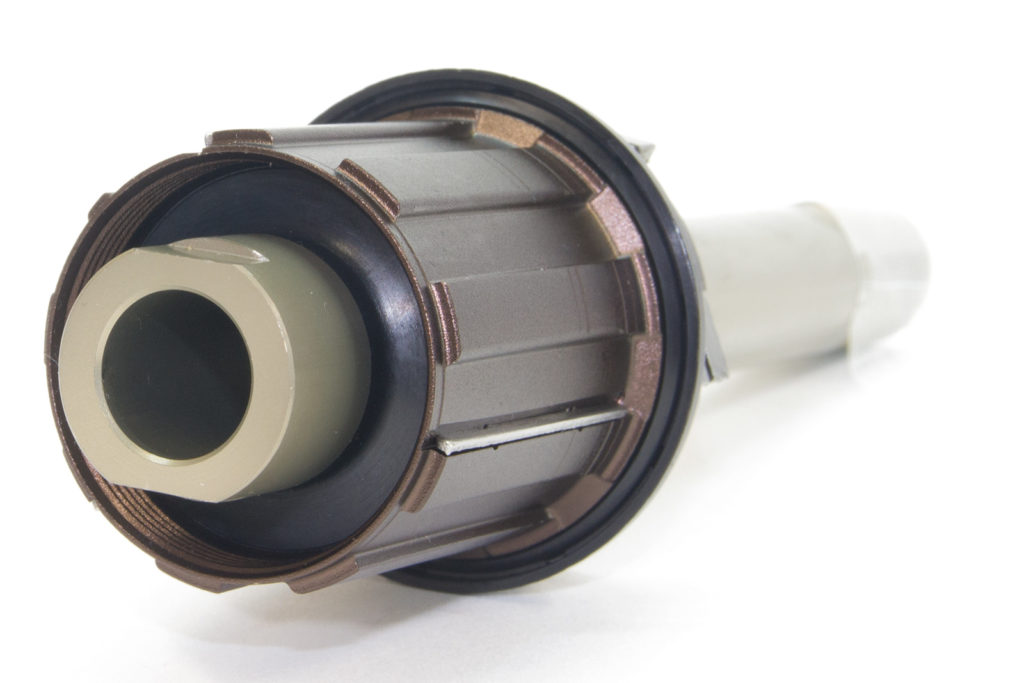

New push-fit axle system

Most of our disk hubs now come with the new push-fit axle system. This makes servicing your hubs even easier and the axles are available to retrofit to older hubs.

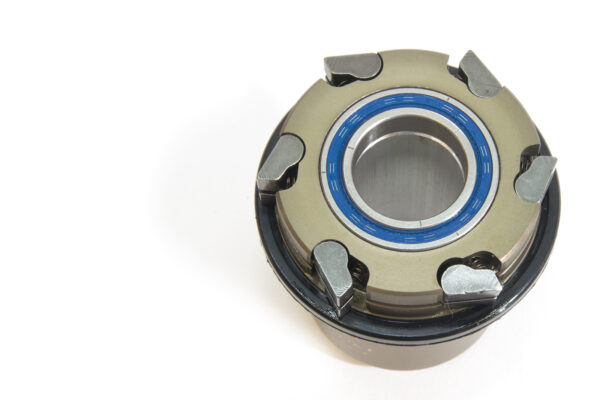

Fast Engagement

All JRA freehubs have 6 individually sprung pawls for quick, reliable engagement. The pawls work in two sets of three, resulting in 48 (road) or 54 (MTB) points of engagement with reliable performance under tough conditions.

Anti-bite guard

Anti-bite inserts prevent cassette gouging. Three stainless steel splines inserted into the freehub add almost no weight while effectively preventing the cassette from digging in to the softer aluminium.

Well sealed

Fitted rubber seals on both ends of the freehub keep dirt and water out.

Stainless bearings by TPI

TPI Stainless Steel bearing are the best we have found and we have specified them in all of our hubs except in a small number of bearing sizes that are not available. In that case we use TPI steel or Enduro instead. They make up a large proportion of the cost of the hub but they run smoother and last longer than any others we have tried.

Our Core range uses the TPI plain steel bearings to save cost but the quality is still exceptional.

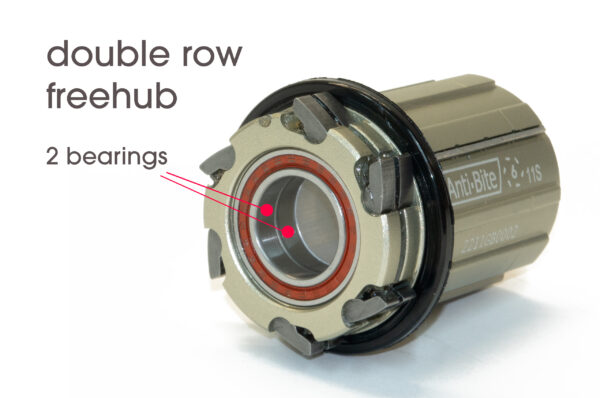

Bitex are best !

Bitex hubs are premium Taiwanese hub manufacturer, out of all the hubs we have built with in the past including Hope, Chris King, Industry Nine, Carbon-Ti, Tune they along with DT Swiss have proven to be the most reliable in normal use. They are mainly used by hand wheel builders and are rarely found in pre-built factory wheel sets due to their high cost. We spec our hubs with TPI bearings either stainless or plain steel and putting two bearings on the drive side of the freehub for added robustness. This adds to the cost but increases reliability.

Double-row bearings

Our hubs have 2 bearings together on the drive-side of the hub, this makes them more resistant to distortion when you are pedalling and putting power though them. This has become an increasing problem with gravel wheels, 29er and 1x drive trains, all adding to the amount of torque going through a bicycle wheel.