Hand building wheels in the UK.

During the building process all components are bedded in, stretched, and tensioned repeatedly until they settle into their final state so the wheels won’t go out of true or lose tension. We inspect, check and finish every wheel with equal care whatever the price.

We have been building wheels for around 15 years and in 2017 moving towards our own wheel range gives us the consistency of product and supply to build accurate wheels every time. It enables us to continuously improve on the process and the products we sell to deliver the best wheels.

Every wheel is expertly built from start to finish in our York workshop with all components checked and prepared before building. During the building process the wheels are bedded in, stretched, and tensioned repeatedly until they settle into their final state so they won’t go out of true or lose tension. All wheels are trued on our P and K Lie jig for maximum accuracy and consistency. We inspect, check and finish every wheel with equal care.

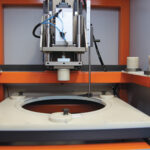

Recent investment in machinery means we can speed up the wheel building during the lacing processes where there is no advantage to hand building, and in fact the machines used correctly are more accurate and can achieve better tension with less damage to the nipple. The detensioning press replaces the old technique of squeezing by hand, or for stiffer wheels, the not-very-well-kept secret of jumping on the wheels to bed in the spokes and nipples. The manual methods are flawed by the fact you can only put pressure on 2 spots on the rim and not in an even way, leading to inconsistencies and distortions in the wheel while the press applies even tension around the rim for more accurate wheels which stay tensioned better.

Efficiencies in production enables us to concentrate our time on finishing the wheels to the same high standard we always have.